|

A little more information on the input data.

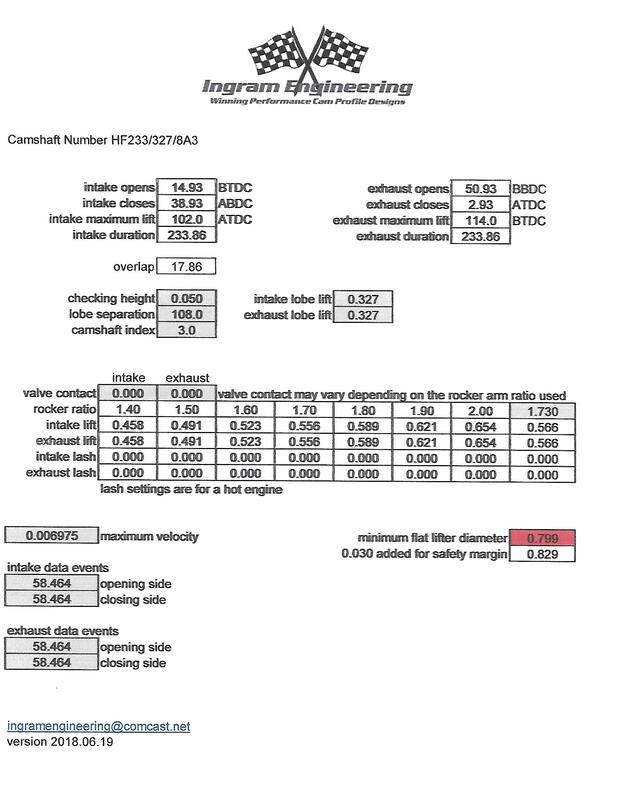

DURATION - The duration at .050 and the lift are usually already known inputs when designing a cam profile. The duration input number will adjust the duration of the profile. Generally the focus is the duration at .050 but it can be anywhere. The angle on the lift table is 1/4 of the crankshaft duration. NOSE ACCELERATION - The nose acceleration is the lowest acceleration at the nose of the lobe (0-degree). The velocity is decreasing to zero so the nose acceleration is a negative number. The number is usually between -.00015 and -.00035. Changing this number will change the entire profile. Nose acceleration is a main input. RAMPS - The input numbers for the ramps were mentioned in lesson two. The valve closing velocity is usually under 40-inches per second for a modern high-end valve train. Other applications are around 30-inches per second. Tappet lash opening velocities are usually less than .002-inches per degree for a solid tappet. The same ramps can be used with different profile designs. New ramps do not have to be designed for each profile. Save your ramp designs. DATA POINT - This is not necessary to design the lobe, it is just for information. It is the tappet lift at top dead center depending on the indexing of the camshaft in the engine. The angle on the lift table is 1/2 of the crankshaft angle. OFFSET - Amount the lifter bore is machined with a rotational offset to the camshaft lobe. Can be a positive or negative number. Use 0.000 unless the offset is known. EXPONENTS - Used in the mathematical equations in the program to design the cam profile. Changing any exponent will generally affect the entire profile. Each exponent must be different. The first exponent is usually the number two. Exponents are main inputs. My lobe design form will give me the duration, lift, base circle diameter, hydraulic or solid profile, flat or roller tappet, rocker arm ratio, some engine details and the application. That gives me all the information to design the lobe profile. If you like to work with valve lift data, that's fine, just use your valve lift curve and rocker arm ratio and work backwards. The duration input number will determine the duration at .050 (or anywhere). This number is also the angle on the lift table where the ramp and the profile meet. If the ramp has a height of .020, the duration input number will also be the duration at .020. The nose acceleration and the exponents will be the inputs used to "fine tune" the cam profile. The other inputs have already been determined and will not generally need to be changed. As you can see there is no "magic" involved in this. Just a bunch of numbers that will make up the lift and duration of the lobe profile. The velocity, acceleration, and jerk numbers are important to look at and understand how they affect the profile. Any magic is in the cam designer's knowledge and experience. The last and most important step is to make the camshaft. If you are a camshaft grinder, use the lift table to make a model lobe and then a master plate or send the lift table to someone that can CNC a master plate for you. If you have a CNC cam grinder, you know what to do. If you are not a camshaft grinder, send the lift table to someone that can manufacture the camshaft for you. Below is my valve timing sheet to go with the finished camshaft ground on 108-degree lobe separation with 3-degrees advance.

6 Comments

Alf8772

2/6/2024 19:48:08

Good night, Mr. Ingram. I had not had time to write to you due to some family problems. I have some questions but there is one that most attracts my attention. I have understood almost all your articles on camshaft, I continue reading and reading to learn more. I saw some ramp and profile graphs by Mr. Harvey Crane on the Speed Talk forum, in almost all of them i could see the opening and closing ramp, each lobe profile being symmetrical, but there was one I couldn't distinguish the ramp, the one called "No pulse ramp". My question is this: is the ramp too small? Or is it, as you wrote in lesson number 1, is it a modern profile that doesn't have opening ramp?

Reply

Michael Ingram

2/7/2024 09:06:33

I also sent you an email. I think the "no-pulse" ramp was seen or actually not seen on the acceleration curve. There would be no "dip" on the acceleration curve like some of the other ramps. It is still a ramp, just not designed with the de-acceleration dip. This area is where the velocity is decreasing. Usually the lash is set in this area. This type of ramp is used on the closing side more than the opening side.

Reply

Alf8772

2/7/2024 16:40:24

Good afternoon, Mr. Ingram. I checked and I didn't get any email.

Michael Ingram

2/9/2024 20:54:02

The sentence above "This area is where the velocity is decreasing." should say "This area is where the acceleration is decreasing." The velocity is not accelerating as much and there is a slight dip in the acceleration curve.

Michael Ingram

2/7/2024 17:08:43

I show that the email was delivered to that address. If you have a spam folder, check that.

Reply

Alf8772

2/10/2024 08:25:04

Good morning, Mr. Ingram, I did receive your email and I responded. Excuse the delay. Also, thank you for explaining the sentence above to me, I understood it perfectly. And more after reading again all the classes.

Reply

Leave a Reply. |

Archives

July 2024

|