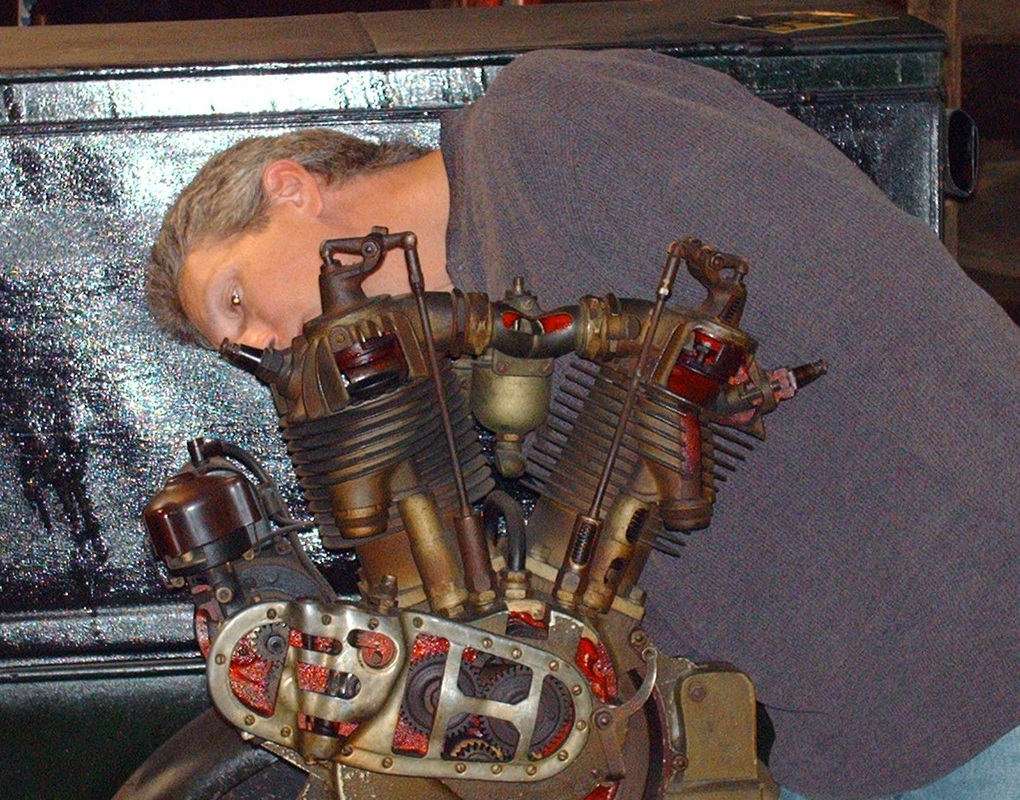

The above photo was taken at the Wheels Through Time museum in Maggie Valley, North Carolina. It is more about showing the engine than me. It is a Harley-Davidson F-head V-twin engine from around the 1920's which has been modified so the internal components can be seen and studied. Many of the early engine performance modifications, including cam profiles, were done on motorcycle engines. This valve train is much different from the typical push rod engines today. Earlier single cylinder motorcycle engines worked with an atmospheric intake valve and did not even have an intake cam profile. This is a good place to start learning for anyone interested in camshafts and cam profile designs.

My name is Michael Ingram. I worked in the performance camshaft manufacturing industry over 34-years before deciding to retire and started this cam profile design service in 2010. At various times I have been involved in almost every aspect of the camshaft manufacturing process. I worked at Reed Cams, Inc. during a time when new technology was first being used in the racing industry. Computers were being used to design cam profiles along with other engine components and even complete race cars. Aerodynamics was being studied and wind tunnel testing was being used to find the best car body shape. Many new innovations were being discovered to make race cars more powerful, faster, and safer. It was a great time to be involved in the sport. For several years I assembled racing engines made up of components that were either modified or manufactured in house at Reed. I also modified Holley carburetors for many years. A large number of those modified carburetors were used by the top teams in NASCAR. I learned much about the inner workings of the internal combustion engine during that time. I continue to learn as I am constantly reading and studying material on these subjects along with my other interests and activities. I believe one should never quit learning.

The "PHOTOS" page shows some of the race car teams and engine builders I ground camshafts or built carburetors for (or both) back in the day with Reed Cams. Reed Cams, Inc. was one of the few shops in the country, at the time, that built racing engines, ported cylinder heads and intake manifolds, modified Holley carburetors, designed cam profiles and ground camshafts, and had a sophisticated engine dynamometer and the latest flow benches. Business was all done under one roof and the products and services were available to anyone. I was very fortunate to have learned from John Reed and others and been able to take part in all of that. Sadly, Reed Cams, Inc. is no longer in business but contact me if you need some information about a Reed camshaft or carburetor. I can also supply the original cam profile design for many of the popular Reed cam profiles.

Being an independent designer allows me the luxury of spending as much time as needed on each cam profile design to make it the best it can be. I can also do it for much less than the cost of your time or hiring another employee and buying a new computer and design software. I would truly appreciate the opportunity to earn your business. Do not hesitate to contact me with any questions you have. All of your cam profile design data and your identity will be kept completely confidential. I will never release information on anyone's cam profiles or who I do designs for. All of that information is secure and stays with me. If you wish to have a signed contract, that is fine with me.

Thank you for visiting my website. Check back often as I am always updating the website and trying to improve my service. There is a lot of good information posted on the "CAM TALK" page and you can gain a little insight into my thoughts and ideas. Please leave any helpful comments or send me an email.

My name is Michael Ingram. I worked in the performance camshaft manufacturing industry over 34-years before deciding to retire and started this cam profile design service in 2010. At various times I have been involved in almost every aspect of the camshaft manufacturing process. I worked at Reed Cams, Inc. during a time when new technology was first being used in the racing industry. Computers were being used to design cam profiles along with other engine components and even complete race cars. Aerodynamics was being studied and wind tunnel testing was being used to find the best car body shape. Many new innovations were being discovered to make race cars more powerful, faster, and safer. It was a great time to be involved in the sport. For several years I assembled racing engines made up of components that were either modified or manufactured in house at Reed. I also modified Holley carburetors for many years. A large number of those modified carburetors were used by the top teams in NASCAR. I learned much about the inner workings of the internal combustion engine during that time. I continue to learn as I am constantly reading and studying material on these subjects along with my other interests and activities. I believe one should never quit learning.

The "PHOTOS" page shows some of the race car teams and engine builders I ground camshafts or built carburetors for (or both) back in the day with Reed Cams. Reed Cams, Inc. was one of the few shops in the country, at the time, that built racing engines, ported cylinder heads and intake manifolds, modified Holley carburetors, designed cam profiles and ground camshafts, and had a sophisticated engine dynamometer and the latest flow benches. Business was all done under one roof and the products and services were available to anyone. I was very fortunate to have learned from John Reed and others and been able to take part in all of that. Sadly, Reed Cams, Inc. is no longer in business but contact me if you need some information about a Reed camshaft or carburetor. I can also supply the original cam profile design for many of the popular Reed cam profiles.

Being an independent designer allows me the luxury of spending as much time as needed on each cam profile design to make it the best it can be. I can also do it for much less than the cost of your time or hiring another employee and buying a new computer and design software. I would truly appreciate the opportunity to earn your business. Do not hesitate to contact me with any questions you have. All of your cam profile design data and your identity will be kept completely confidential. I will never release information on anyone's cam profiles or who I do designs for. All of that information is secure and stays with me. If you wish to have a signed contract, that is fine with me.

Thank you for visiting my website. Check back often as I am always updating the website and trying to improve my service. There is a lot of good information posted on the "CAM TALK" page and you can gain a little insight into my thoughts and ideas. Please leave any helpful comments or send me an email.

Michael Ingram

Lawrenceville, Georgia

770 312 5623 (voice phone only, no text messages)

[email protected]

LinkedIn

Lawrenceville, Georgia

770 312 5623 (voice phone only, no text messages)

[email protected]