Ingram Engineering Cam Profile Designs is a lobe profile design service for camshaft grinders, engine builders, and anyone needing a specific cam profile design. Cam profile designs are furnished with the lift and design data along with .s96 and Landis .p programming files. Each cam profile design is exclusive to the original customer and will not be shared with anyone. All of your information is kept completely confidential.

Cam profiles are computer designed using various software programs that displays the lift table data out to eight decimal places. All of the important parameters are analyzed when designing a cam profile including the velocity, acceleration, jerk, radius of curvature, and pressure angle. My approach is to create a cam profile with as much area as possible under the higher part of the lift curve and still maintain smoothness and reliability for the application. This is an approach that has been proven again and again to be successful at producing a winning performance cam profile.

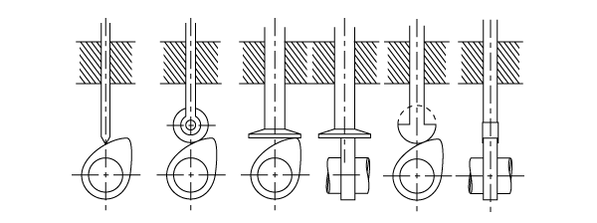

Flat Tappet Profiles

Flat tappet profiles are designed for a specific base circle diameter of the lobe and tappet diameter. These cam profiles are designed with an adequate nose radius and edge margin to promote longevity and prevent premature wear to the camshaft and flat tappet. Special techniques can also be applied to control the maximum velocity when necessary on some designs.

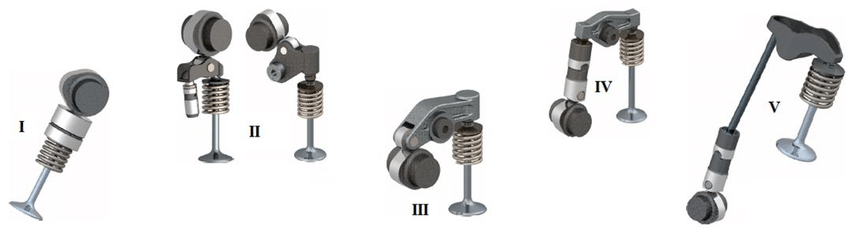

Roller Tappet Profiles

Roller tappet profiles are designed for a specific base circle diameter of the lobe and roller wheel diameter. These cam profiles can be designed with or without a negative radius of curvature (inverted flank). Conservative pressure angles are used to promote longevity and prevent premature wear to the camshaft and roller tappet. Special techniques can also be applied to control the maximum acceleration when necessary on some designs.

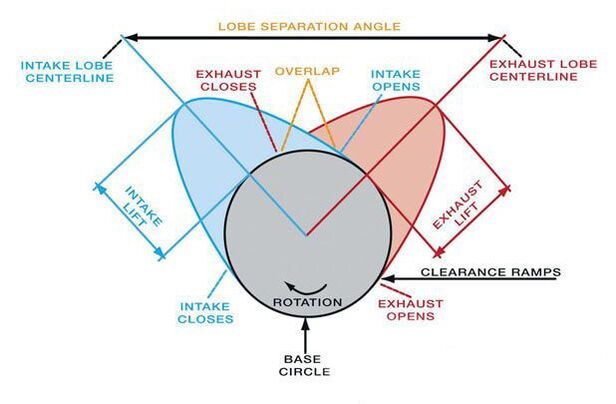

Profile Ramps

Solid and hydraulic ramps and opening and closing ramps all have their own unique designs that contribute to creating a smooth, quiet, and reliable cam profile. Custom software is used to design these profile ramps that allow the valve opening and closing points to be placed exactly where they need to be.

Cam profiles are computer designed using various software programs that displays the lift table data out to eight decimal places. All of the important parameters are analyzed when designing a cam profile including the velocity, acceleration, jerk, radius of curvature, and pressure angle. My approach is to create a cam profile with as much area as possible under the higher part of the lift curve and still maintain smoothness and reliability for the application. This is an approach that has been proven again and again to be successful at producing a winning performance cam profile.

Flat Tappet Profiles

Flat tappet profiles are designed for a specific base circle diameter of the lobe and tappet diameter. These cam profiles are designed with an adequate nose radius and edge margin to promote longevity and prevent premature wear to the camshaft and flat tappet. Special techniques can also be applied to control the maximum velocity when necessary on some designs.

Roller Tappet Profiles

Roller tappet profiles are designed for a specific base circle diameter of the lobe and roller wheel diameter. These cam profiles can be designed with or without a negative radius of curvature (inverted flank). Conservative pressure angles are used to promote longevity and prevent premature wear to the camshaft and roller tappet. Special techniques can also be applied to control the maximum acceleration when necessary on some designs.

Profile Ramps

Solid and hydraulic ramps and opening and closing ramps all have their own unique designs that contribute to creating a smooth, quiet, and reliable cam profile. Custom software is used to design these profile ramps that allow the valve opening and closing points to be placed exactly where they need to be.