|

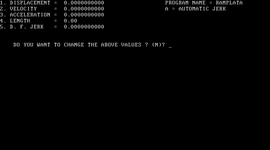

Welcome everyone, sit anywhere you like. These first lessons will be a simple introductory approach to the cam profile design process using data and images from the design software. I would recommend taking notes, there will be too much information to try and remember. The two main programs of the software package are the ramp design program (ramplatb.exe) and the profile design program (prof386d.exe). Another main program (camplotd.exe) will create the finished lobe profile after you successfully design the opening and closing ramps and the opening and closing profiles. I say successfully because this entire process is trial and error until the desired lobe design is reached. If the numbers you enter do not compute, you can not continue. I usually design the ramps first. The ramp is just that, a ramp. I like to use examples to help explain stuff. A motorcycle jump is an easy way to visualize a ramp. There is a launching ramp and a landing ramp. Each ramp is designed for a particular task. In cam design sometimes the opening and closing ramps will be the same. Sometimes the opening and closing profiles will be the same. This is known as a symmetrical profile, same opening and closing. We will design a symmetrical profile since it is simpler. It will be a hydraulic flat tappet profile for a small block Chevrolet 350 V8 engine. Below is the ramp design input screen. The ramp will begin at zero tappet lift and end at some point that you choose. These input numbers are for the end of the ramp. DISPLACEMENT = [tappet lift at the end of the ramp] VELOCITY = [at the end of the ramp] ACCELERATION = [at the end of the ramp] LENGTH = [length of the ramp in degrees] D.F. JERK = [degrees of final jerk at the end of the ramp, enter "A" and the program will automatically calculate the final jerk and the number of degrees] Some designers don't pay a lot of attention to the ramp design. It's probably not as important today with better valve springs and a more ridged valve train. When I started designing, the ramp design was important, so I still pay close attention to it. The most important part is how fast the valve closes against the seat. Obviously engine rpm, rocker arm ratio, and valve lash will need to be taken into consideration when designing the ramps. I keep a library of various ramp designs for different applications. Ramps that I have designed and used over the years and some that are taken from camshafts that I have analyzed. A lobe can actually be designed without ramps. Many of the original 3-arc cam profiles did not have ramps. Later with 6-arcs they did include ramps. Some modern profiles are designed without an opening ramp. Just like the lobe profile, the ramps are created by the designer. Just like the lobe profile, it is a trial and error process. It all comes with time and experience. Don't get discouraged.

0 Comments

Leave a Reply. |

Archives

July 2024

|